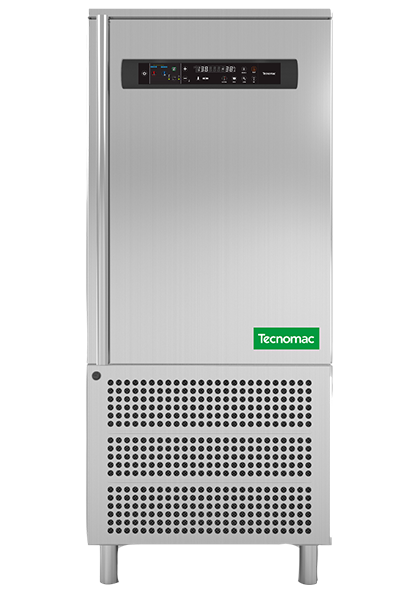

V 10.35

Brand : TECNOMAC

Main functions

Blast chilling / Shock freezing

The most advanced chilling / freezing solutions in order to ensure quality and hygiene in food processing.

Thawing

Thawing by forced ventilation.

Icecream

A specific and dedicated function for ice cream.

HACCP control

Cycles details can be easily stored on an USB stick, in compliance with HACCP guidelines.

Sanification

The highest hygiene levels are guaranteed by an ozone device (optional)

แบ่งปันให้เพื่อนของคุณ

| Dual suitability trays rack |

Suitable

for both GN1/1 and EN 600 x 400 mm trays. Easily removable for

cleaning, it is designed to facilitate the chilling air flow, increasing the

machine efficiency. |

| Evaporator |

Easy

to inspect and with hot gas defrosting, painted against corrosion risks. Indirect air flow. |

| Core probe |

Automatically controls the length of the blast chilling cycle. Conic

shaped, can be easily removed after the cycle, no heating needed. The

double probe is available as an option. |

| Ozone sanification |

Sanitizes

the blast chilling chamber after cleaning the machine. Useful also to sanitize

working tools.(optional) |

| Output chilling (+90°C > 3°C) |

35 kg. |

| Output freezing (+90°C > -18°C) |

25 kg. |

| Dimensions |

840x 831x 1498 : 1558 mm. (WxDxH) |

| Voltage |

400 V - 3/50Hz |

| Capacity |

10 trays (600x400 GN1/1) |

| SPEC SHEET | เปิด |