| FEATURES : |

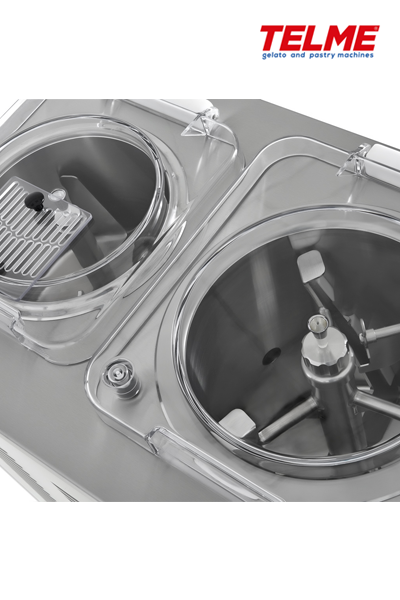

- The cylinder is vertical with important

advantages: easy

filling, constant visibility of the product and addition at any time of liquid,

powder and solid ingredients. - Fitted with separate heating and cooling for production

in sequence.

- Ideal for making gelato with specific recipe such

as chocolate: white,

milk, sweet, dark, bitter, etc. |

| MAIN FUNCTIONS : |

- Mixing and blendingof ingredients: milk, cream, milk powder,

sugar, dextrose, eggs emulsifiers, stabilizers, etc.; necessary for the

preparation of gelato, sorbetto and slush. - Heating and sanitizing: melts sugars, melts

fats & chocolate, hydratates stabilizing agents and solid parts, emulsifies

fats with water and eliminates the most of pathogenic bacterial flora. - Cooling and finalizes pasteurization. Thermoshock system (M.O.P.) to process hot

mixes. - Freezing the liquid mix and incorporating air

into the product.The

smooth mechanical and thermal treatment produces a fine and creamy ice cream or

gelato. - Rapid and complete discharge of gelato

ready to be served. - Conservation at the end of the cycle to help the

operator.

- Self-diagnosis to help the technical assistance. |

| TYPE OF USE AND PRODUCTS : |

GELATO & ICE CREAM - Pasteurizing - Gelato - Sorbetto - Icecream

(own production)

- Slush |

| FUNCTIONAL DATA : |

factory settings - Heating

program: Adjustment

range +65°C

÷ +90°C – Factory setting +85°C

- Freezing

program: Adjustment

range-12°C

÷ +6°C – Factory setting -9°C |

| . |

|

| SPEC SHEET | เปิด |